Cable Percussive Boreholes as part of Site Investigations

Cable Percussive Boreholes are an intrusive site investigation technique used to establish the ground conditions and soil parameters of a development site. As part of Environmental and Geotechnical Site Investigations, Cable Percussive Drilling provides information used to inform geotechnical design, especially foundation designs for development sites pre-planning preparation. Or to advise on the most suitable Geo-environmental or Geotechnical designs for the proposed construction.

What is a Cable Percussive Borehole?

Cable Percussive Boreholes also known as “shell & auger” boreholes are the most common drilling method for boreholes used for geotechnical site investigation, and can be used for a variety of tests including:

- standard penetration testing (SPT)

- cone penetration testing (CPT)

- permeability testing

- borehole vane testing

The boreholes can also be used for the installation of a wide range of gas, groundwater, and geotechnical monitoring. This monitoring equipment can be installed in the borehole to allow later measurements when required.

How Does Cable Percussion Borehole Drilling work?

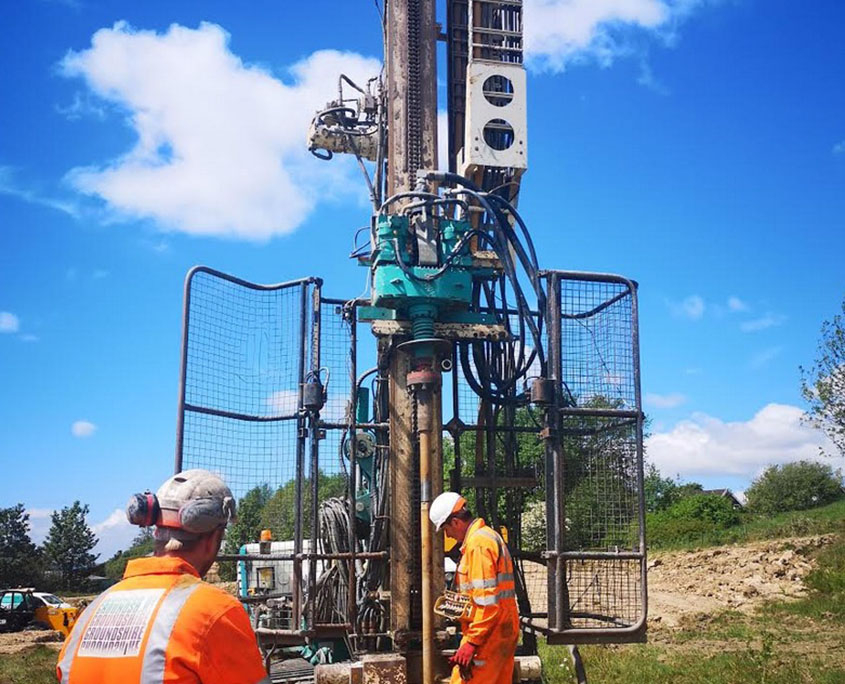

Using a land rover, or four-wheel drive vehicle, the drilling rig can be towed to a wide variety of terrains. If there is restricted access a specialist adapted rig can be used, or the drilling rig can be positioned by a crane if required.

The rig has a large tripod and a winch which is used to lift and drop the heavy cutting tool. This drop tool-type drilling method uses steel casing tubes to prevent the collapse of the borehole during drilling. Different cutting tools are used depending on the type of soil and subsurface the tool is cutting through.

The borehole is advanced down using the appropriate cutting tool, which is lifted and dropped repeatedly, the cutter is attached to a “cable” to lower the cutting tool down. As the percussive drilling advances borehole casings are lowered down to ensure stability is maintained.

In situ testing can be completed at various depths as the borehole advances down. Samples can also be taken for laboratory testing to assess contamination and soil structure. Cable percussion boreholes can be used to investigate the soil profile to much greater depths than window sample boreholes. Used for geotechnical site or ground investigations, Cable Percussive Borehole drilling can sample depths of up to 60m.

If you are planning any development involving construction, you will most likely require a site investigation to get an understanding of the sub-surface ground conditions of your development site.

The site investigations will be used to collate interpretive reports and used to provide advice on foundation design solutions, contamination levels, and remediation strategies for the specific development site.

At Earth Environmental & Geotechnical we recommend discussing your development site proposals at an early stage, we can offer advice, recommend investigation techniques and suggest scopes of work which will help with your development designs and subsequent planning application approval.

Frequently Asked Questions.

What is a Cable Percussive Borehole?

Cable Percussive Boreholes are an intrusive site investigation technique used to establish the ground conditions and soil parameters of a development site.

How does Cable Percussion Borehole Drilling work?

A drilling rig consists of a large tripod with a winch. The appropriate cutting tool, which is attached to a cable, is repeatedly lifted and dropped. The cutting tool advances through the sub surface forming a borehole. The percussive drilling technique allows for a borehole casing to be installed inside the hole, this prevents loose soil from collapsing into the hole as the drilling rig progresses down.

What is Cable Percussion Drilling used for?

Disturbed and undisturbed samples can be retrieved from the boreholes at regular intervals. These samples are inspected and logged by our engineer and can be tested in situ or in a laboratory to assess for contamination and soil structure.

The results of the cable percussive borehole sampling are used to establish the ground conditions of a development site. The data provided is used to inform geotechnical design, especially foundation designs for development sites preplanning preparation.

Earth Environmental & Geotechnical offer Cable Percussive Borehole drilling throughout the UK as part of their Geotechnical and Environmental Site Investigations Services. Before any site investigations commence it is important to understand your development sites ground conditions and what Ground Investigation techniques are most appropriate.

If you would like to discuss your development site, call our Head Office on Tel: 0161 975 6088

Many site investigations are conducted to discharge planning conditions and our staff always ensure, time permitting, that prior to delivery of a costed proposal an outline of the proposed works is initially discussed with the regulatory authorities.

Our staff have extensive experience in the design of geotechnical, mining and environmental site investigations in accordance with current best technical practices and planning guidance. The team are able to manage geotechnical and geo-environmental investigations for the most demanding of sites. Our multidisciplined teams include engineers, geologists, environmental scientists, drillers and technicians who are experienced in all aspects of ground investigation and remediation works.

In-house drilling rigs are wherever possible used for drilling work, with approved quality sub-contractors used for projects (where necessary).