Subsurface Site Investigations are required to get a full understanding of what you are building on. The first stage in the process is the Phase 1 Desk Study. The results of the phase 1 Desk study combined with the Preliminary Development Design Proposal will inform what Site Investigations are required next.

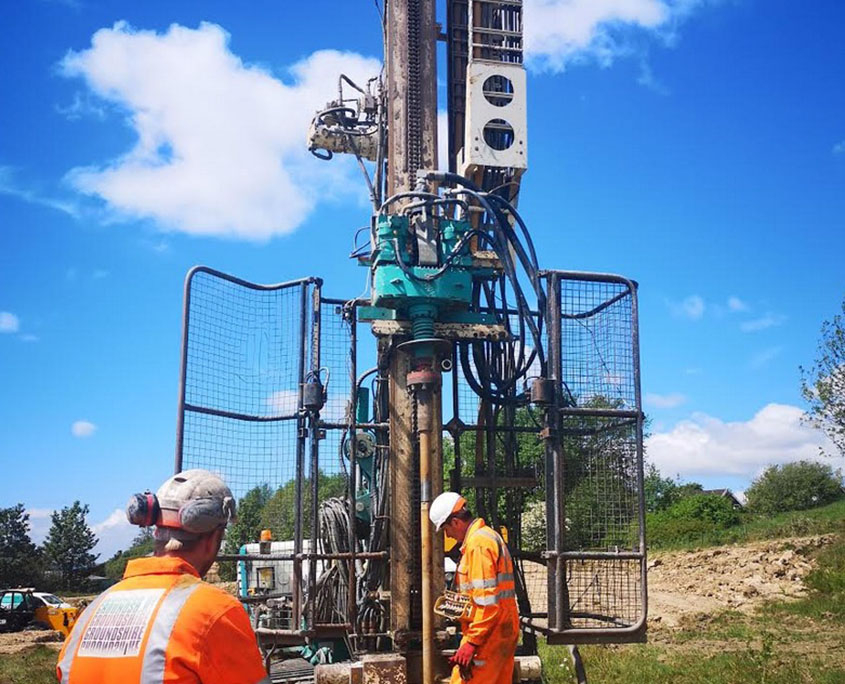

Site Investigation services include subsurface exploration and laboratory analysis to establish ground conditions for development sites. These Site Investigation techniques include trial pits, rotary drilling, and window & windowless sampling and cable percussive boreholes

Any site investigation should ideally follow the development of a site walkover survey and desk-based study (Phase I Desk Study) using readily available publically archived information (historical, environmental, mining etc) that allows for a cost effective strategy to be implemented. The defined scope of work within any preliminary investigation is paramount for a successful project to be completed, the old adage “you pay for a site investigation whether you have one or not”, is commonly quoted to clients!

All site investigations are conducted in accordance with strict and well-defined health and safety practices with site-specific method statements and risk assessments provided. Prior to commencement on-site service (gas sewers, electricity etc.) information is acquired from the client (or its agents) with utility tracing conducted, if required.

Many site investigations are conducted to discharge planning conditions and our staff always ensure, time permitting, that prior to delivery of a costed proposal an outline of the proposed works are initially discussed with the regulatory authorities.

Our staff have extensive experience in the design of geotechnical, mining, and environmental site investigations in accordance with current best technical practices and planning guidance.

The site investigation services required will depend on the specifics of the site being developed including the known, strata of the area, if the site is in a coal mining area, the groundwater conditions, and potential contaminants. The known ground conditions will determine what Site Investigation techniques are most appropriate for the specific site and the proposed development. The term ‘ground conditions’ generally refers to the geology, hydrology, soil condition and any contamination of the ground on the site of a construction project. Ground conditions may be naturally occurring, man-made, or, frequently a combination of the two.

In-house drilling rigs are wherever possible used for drilling work, with approved quality sub-contractors used for projects (where necessary).